Warwick and Callan are a father-son team that started focusing on Lighted Mirrors in 2012.

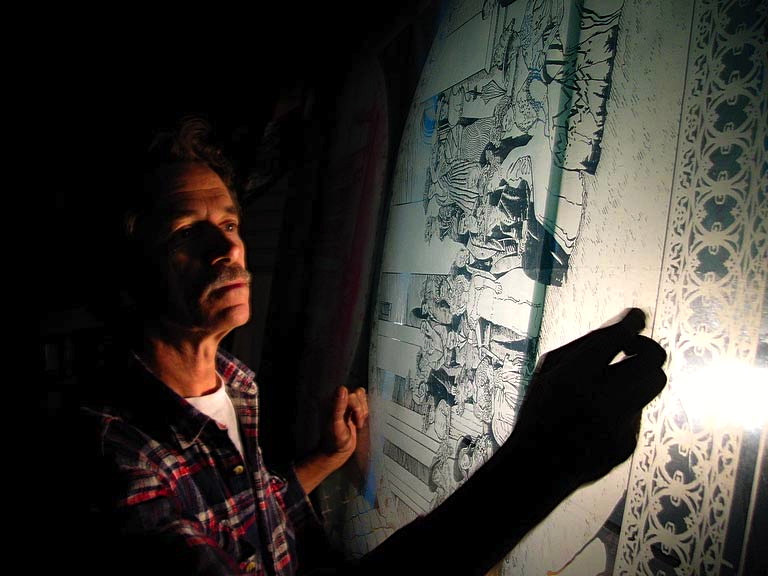

Warwick, with over 25 years and 50,000 hours in glass etching, and Callan, the business-minded son. Together they started the LED Mirror market in Australia.

LED Mirrors were a thing of the future, something only seen in hotels overseas and in magazines.

In 2021 Clearlight Designs was operating out of Byron Bay and had been for the last 25 years as a sandblast glass etching business.

Travelling down to Sydney for Home Trade Shows, Clearlight Designs quickly captured the Sydney market with its incredibly well-made LED Mirrors.

Often future clients did not even know that a product like this existed. Let alone could purchase a custom-sized and Australian-made one.

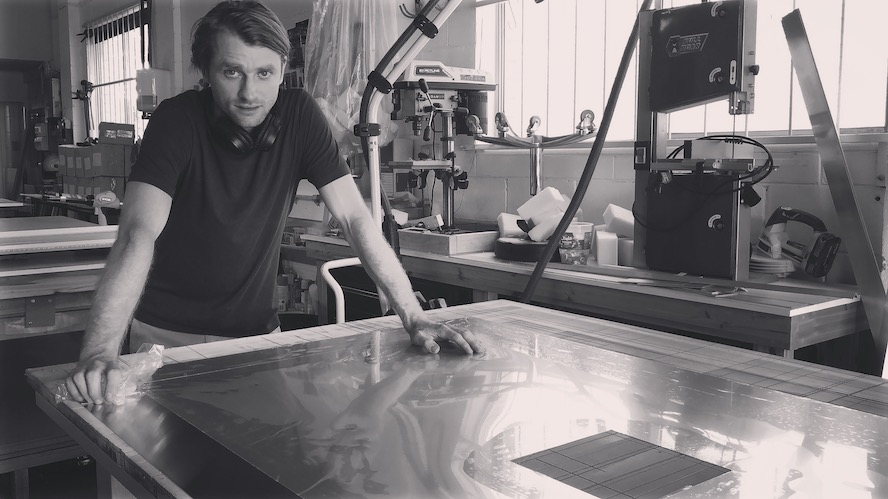

Callan – Managing Director at Clearlight Designs

Our first major client was in 2014 with the refurbishment of the Horizon Suits in the Shangri-La Hotel at the Rocks, Sydney.

After many trips down to Sydney, they soon realised Sydney was the place to be operating out of and in 2015, they moved to Brookvale and started operations.

Orders picked up quickly, and tradeshows had to be abandoned with the amount of work coming in. With clients all over Australia ordering LED Mirrors, and commercial clients such as The Westin Hotel Group, Sofitel, Mantra, Private Hospitals, Top Golf Gold-Coast, Big-W, General Pants, Rebel Sports Etc. Clearlight Designs became the place to get a LED Mirror.

Still, a decade later, Clearlight Designs is the only company in Australia 100% manufacturing LED Mirrors with a 5-Year warranty to the Australian Market. With 100% 5-star reviews on Google and Facebook, our past clients are happy to tell everyone how pleased they are with our products and our unbeaten service.

Pictured at top: Warwick Pascoe, Founder and Active Director

The mirror is only part of the picture. A decade has gone into the development of the backing structures. Which are constantly getting innovated to be the best. The backing structures are made out of aluminium, complete with IP67-rated 12 volt DC electrical components.

We are always on the lookout for a way to improve our product. Our team can implement innovations immediately.

Australian Made LED Lighted Mirror 🇦🇺

Photo: South Yarra, VIC

Australian Made – Australian Owned

We are proud to be Australian Made, and for good reasons. We have purchased other illuminated mirrors from China, New Zealand, Russia, UK and U.S.A., and every aspect of these imported mirrors has been inspected for quality manufacture. They have all proven to be defective, in some way, and not of the high standards that we at Clearlight Designs demand. We design and manufacture the finest-illuminated mirror on the worldwide market. We have done the shopping around for you. Our team can adapt quickly on the factory floor, continually designing and refining the Lighted Mirror.

When a company produces a product offshore, it is incredibly hard to maintain quality control on the product. When other companies in Australia are directly importing illuminated mirrors, they can supply a lighted mirror at a cheaper cost to the consumer. But with that more affordable bottom line, you compromise on the quality of the product.

Lower quality, cheaper imports include

- Quality of the reflectiveness of the mirror

- The thickness of the Mirror-glass

- The rate at the mirror starts to erode and gets that irreversible black creep.

- Cheap plastic backing structure

- Unsafe hanging mechanism

- Grainy frosted strips sandblasted into the mirror

- Low light and short lifespan lasting LED lights

- Placement of the LED lights, which creates Hot Spots

- An uncertified 12volt transformer that powers the lights

- Untested uncertified 240v dangerous de-mister

- Weak cardboard packing box

Clearlight Designs Australian Made Lighted Mirror include

- New Corrosion Free Mirror by AGC Glass Europe. – Beautifully reflective and durable mirror, providing unparalleled protection against corrosion

- Supreme grade sandblasting grit – Achieves smooth, even unbroken frosting

- 100% aluminium backing structure – Light in weight and incredibly strong

- 100% anodised aluminium Twin Double split batten hanging system

- 20mm thin aluminium backing structure (distance from the wall to the back of the mirror)

- 70,000+ hours of 5050 LEDs that output 20 lumens per chip or 1200 lumens per meter

- Optimal placement of LED lights to achieve an even bright light

- Australian certified 12-volt transformers

- Safe and low power eco 12-volt Demister

- Strong custom-made timber packing crate

At Clearlight Designs, we have spent well over half a decade designing and manufacturing our LED Lighted Mirrors.

Every LED lighted mirror that leaves our factory floor has been tested and meticulously checked for defects. Only when the mirror has met our quality control team’s demands is it wrapped and packed in our custom-built timber crate. These crates can handle any delivery transfer and any courier driver. Never has there been any damage to our mirrors in transportation.

Luxury hotels and resorts like The Shangri-la and Sofitel can’t be wrong when they choose Clearlight Designs Lighted Mirrors for their hotel rooms. Countless guests are continually testing the reliability and performance of our mirrors. Here at Clearlight Designs, we are more than happy to offer our product with a 5-year warranty, as we know that our mirrors will last well past the traditional 12-month product warranty.

Photo: The Shangri-la Hotel, The Rocks, Sydney, NSW

We’re certified by and are proudly a part of the Australian Made Campaign. Our office and factory are located in Sydney, Australia. This means we always have full control over the products we are manufacturing. The product above is made in Sydney, Australia. Clearlight Designs is an Australian-owned company. Take trust in knowing that Clearlight Designs is looking after you. To read more about lighted mirrors, check out our blog!